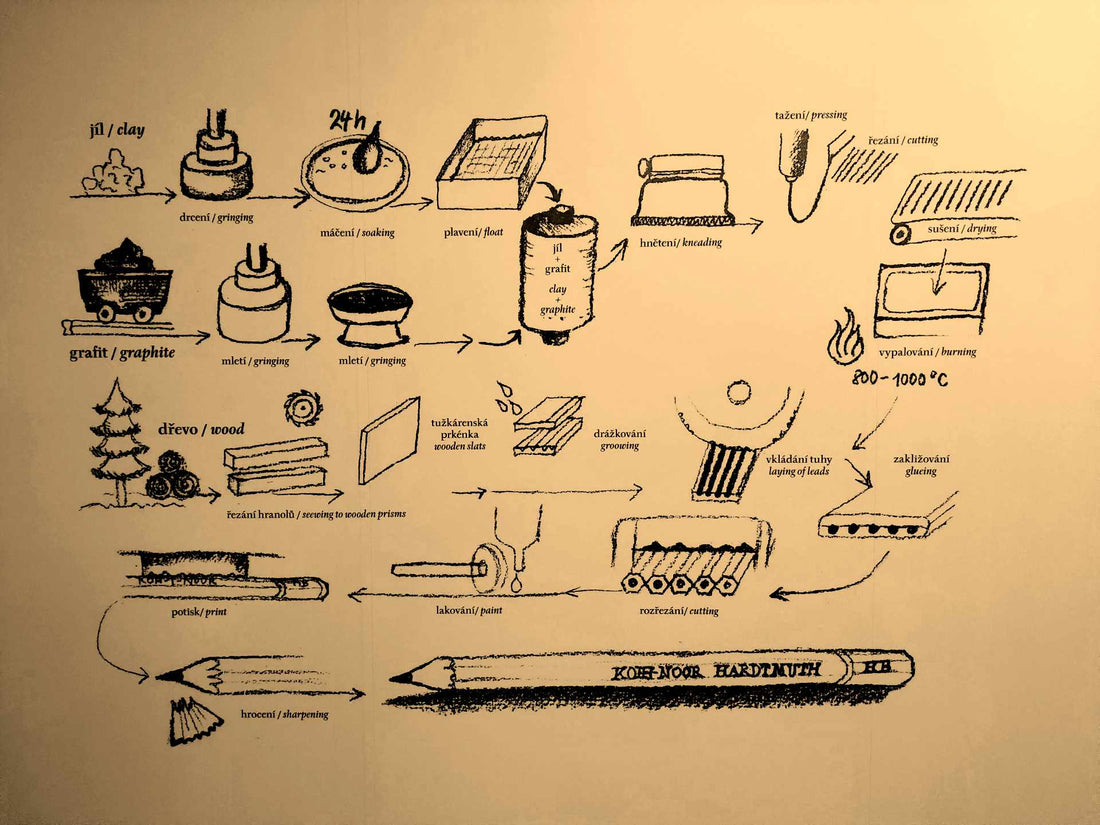

How A Pencil is Made

In 1930, Dr. Jan Dejnek described the process of making a pencil as follows:

Lead sticks are made of lead (graphite) and plastic clay. Various types of lead are being used, with the best being Celyon lead which is suitable for the softest pencils. Czech, Siberian, Mexican and English leads are also widespread.

The Czech graphite mines are distributed in the south of the Šumava Mountains: in Chvalovice, Chrášťany, Hůrka, Černá and Dolní Třebonín municipalities. In Moravia, graphite is extracted near Velká Tresná and Staré Město. According to statistics, in 1925, about 200,000 quintals of raw graphite was extracted in the Czech territory.

Graphite is intended for the production of pencils, being first cleaned through washing, and then a chemical process. After the cleaning, it is mixed with a certain amount of pure plastic clay. Then this mushy mixture is ground is special mills until it has the required softness. The longer the grinding, the softer the graphite mixture, and the better properties the pencils have. Depending on the amount of the admixed clay, pencil hardness is determined.

Once the grinding of the graphite mixture is finished, excess water is removed from it by pressing and drying. By pressing, the graphite mixture acquires a shape of flat plates. Those plates are flattened and kneaded, and then stuffed under pistons into steel cylinders. Every cylinder has a tiny hole at the bottom part, through which the graphite mixture is pressed in the form of a continuous wire which is then cut into pieces about three times longer than the pencils being made. Those pieces are laid one next to another on special small plates which are transported to drying kilns to be dried out to perfection. The drying process is a slow one, and a special attention is paid so that the graphite pieces don’t bend.

After complete drying, they are broken into sticks of pencil length, put into fireclay cups which are closed to become airtight, and then inserted into annealing furnaces where they are heated up until they become white-hot. With this annealing (baking) process, the sticks become hard. Then the annealed sticks are immersed into tallow, wax or stearin to become supple and smooth. And finally, they are cleaned through sawdust. Sticks processed in this way are inserted into wooden covers.

The covers of the cheapest pencils are made from different types of wood (including linden, alder, spruce and others), while more expensive ones are made of (Californian) cedar wood which is coloured to resemble red cedar wood. Red cedar wood is imported from the US and it is used to produce premium pencils, as this type of wood is easy to both work and polish. And, as it is soft, pencils made of red cedar wood are easy to sharpen.

First, the piece of wood is cut into small planks with the length equal to the length of a pencil and a width which is enough to make for six pencils.

Then the planks are grooved, with the grooves having the same shape of graphite sticks,

they are coated with glue, ,

sticks are inserted into the grooves,

and then a second plank, also covered in glue,

is laid down, with both planks being pressed to each other and then being dried.

Once dried, the ends of the sticks are ground off, and then milled off from both sides.

As a result, we get six pencils of rounded, hexagonal or octagonal diameter.

Then the pencils surface is smoothed out, polished, coloured, lacquered, and the pencils tips are cut off neatly,

before being marked by embossing the brand of both the product and factory. This is made at high temperatures using white colour,

brown colour,

silver or gold.

And finally, the pencils are brushed clean in a special machine, and then packed into boxes by the dozen.

Source: Exhibition of the National Technical Museum in Prague, Hardtmuth: From Charcoal to a Pencil Empire.